Basic theory and about product

In the international standard defining DEF (ISO 22241), it is referred to as AUS 32 (aqueous urea solution 32%).

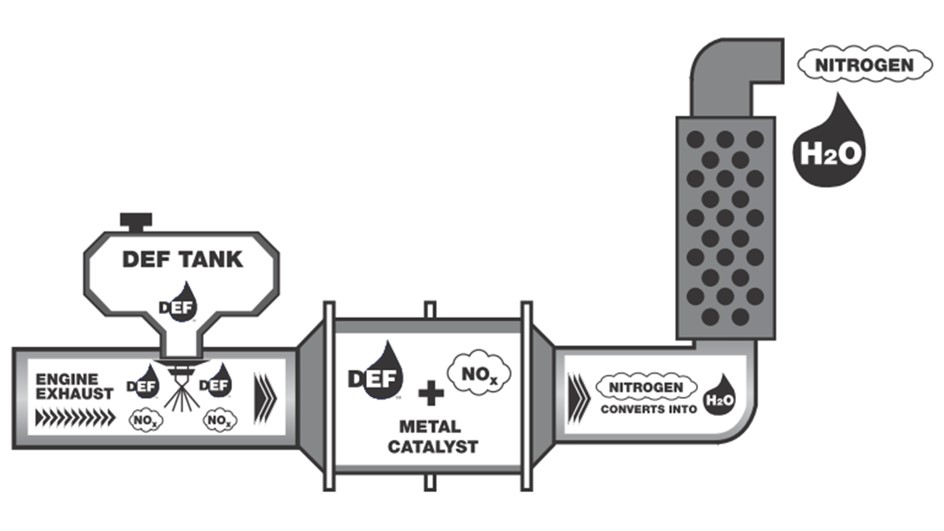

Diesel exhaust fluid (DEF; also known as AUS 32 and marketed as AdBlue) is a liquid used to reduce the amount of air pollution created by a diesel engine. Specifically, DEF is an aqueous urea solution made with 32.5% urea and 67.5% deionized water. DEF is consumed in a selective catalytic reduction (SCR) that lowers the concentration of nitrogen oxides (NOx) in the diesel exhaust emissions from a diesel engine. FLENDS (Final Low Emission New Diesel System)

Diesel engines are typically operated with a lean burn air-to-fuel ratio (over stoichiometric ratio) to ensure the full combustion of soot and to prevent them from exhausting unburnt fuel. The excess air leads to the generation of NOx, which are harmful pollutants, from nitrogen in the atmosphere. SCR is used to reduce the amount of NOx released into the atmosphere. DEF from a separate tank is injected into the exhaust pipeline, and the exhaust heat decomposes it to ammonia. Within the SCR catalyst, the NOx is reduced by the ammonia into water and nitrogen, which are both non-polluting. The water and nitrogen are then released into the atmosphere through the exhaust.

As the DPF does not function with low-sulfur diesel fuel.

The injection rate of DEF into the exhaust depends on the specific after-treatment system but is

typically

2–6% of

diesel consumption volume. This low dosing rate ensures long fluid refill intervals and minimizes the

tank's size and

intrusion into vehicle packaging space. An electronic control unit adjusts the addition of fluid in

accordance with

parameters such as engine operating temperature and speed.

Chemistry

DEF is a 32.5% solution of urea, (NH2)2CO. When it is injected into the hot exhaust gas stream, the water

evaporates and

the urea thermally decomposes to form ammonia (NH3) and isocyanic acid (HNCO):(NH2)2CO → NH3 + HNCO

The isocyanic acid reacts with the water vapor and hydrolyses to carbon dioxide and ammonia:

HNCO + H2O → CO2 + NH3

Overall, thus far:

(NH2)2CO + H2O → 2 NH3 + CO2

Ammonia, in the presence of oxygen and a catalyst, reduces two different nitrogen oxides:

4 NO + 4 NH3 + O2 → 4 N2 + 6 H2O and6 NO2 + 8 NH3 → 7 N2 + 12 H2O

The overall reduction of NOx by urea is then:

2 (NH2)2CO + 4 NO + O2 → 4 N2 + 4 H2O + 2 CO2 and4 (NH2)2CO + 6 NO2 → 7 N2 + 8 H2O + CO2

Operation in wintertime

DEF freezes at −11 °C (12 °F). For the SCR exhaust cleaning system to function at low temperatures,

a

sufficient amount

of the frozen DEF must be melted in as short time as possible, preferably on the order of minutes. For

example, 2010 EPA

emissions requirements require full DEF coolant flow within 70 minutes.

Typically, the frozen DEF is melted by heat from the engine, e.g. engine coolant passing through the DEF tank, governed by a thermostatic coolant control valve. This method may take significant time before the SCR exhaust cleaning system is fully operational, often up to an hour.

Another method to thaw DEF (and thus allow for full SCR operation) is to integrate an electrical heater into the DEF tank. This heater must be sized, positioned, and powered adequately to rapidly melt sufficient frozen DEF. It should preferably be self-regulating not to overheat if (part of) the heater is outside of the liquid. It should also preferably be self-regulating to eliminate any complicated sensor and temperature regulating systems. Furthermore, the heater should not exceed 50–60 °C (122–140 °F), as DEF begins to decompose at around 60 °C (140 °F). PTC heaters are often used to achieve this.